We here at BMH are proud to say we are now a distributor for Marzocchi and working with them to provide the very best we can both offer

There has been so much contraversy over the newest release of the Marzocchi Gear. We have been working hand and hand with the engineers to correct the previous problems that have plagued this to try and help resolve this matter. I've spent hours doing research and testing and have found several problems.

I will finally speak the truth, and reveal what has been done to correct these issues.

1) The relocation and over sized pressure port

2) excess lap tolerence

3) incorrect hardware,mounting of gear

4) Over sized suction port

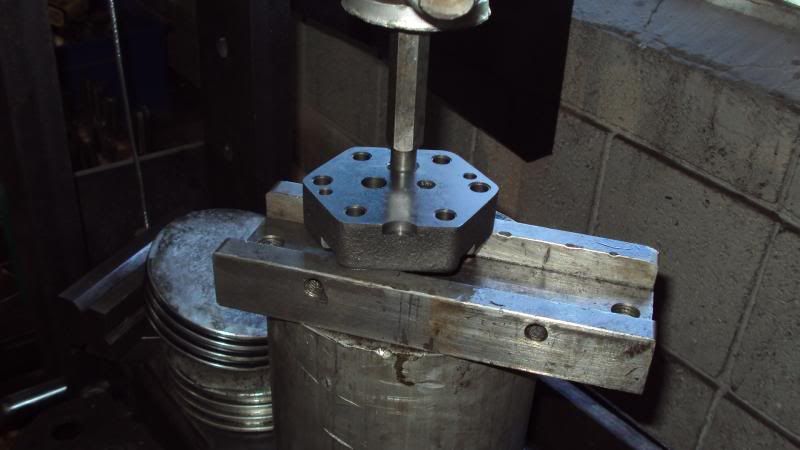

Here are some Photos of corrections being performed

![]()

Insert sleeve 308 stainless, .505 O.D with .050 wall thickness ,is pressed into the .500 pressure port thus making the new port size .400 and keeping port in stock location , making them useable on industry standard block..no new block needed

![]()

Adhesive and sleeve being pressed in

![]()

![]()

Pressed in flush with base. The smaller port makes the gear not flood out as with the bigger port. The larger port definatly has much more flow, but we've achieved a happy medium and get both higher pressures with high flow rates.

![]()

![]()

![]()

with a 20 Ton press the swedge is pushed into the sleeve and flares inside cavity and port

Completed base plate with mating surfaced lapped flat ,where the pretruding flared edge stuck above surface. the top edge of port was machined at a 45 degree counter sink to allow flare to seat and will also not allow it to back out, locking under center section of the gear.

Then the gears center sections are lapped back to Marzocchi specs.

We left the main suction port alone, even know it is over sized by industry standard. Normal port sizing is 40 to 60 % larger for suction port then pressure port. The only down fall I seen from this over sized port is the strength loss taken away of the center section. But ,By using our To-Mar "Gear clamp" this adds the additional strength needed during pressure spikes that would swell or distort this aluminum center section

The last issue I've seen is the incorrect use of pump hardware. The new gears have a cast iron (ductile) top and bottom plate, and are machined flat where mounting hole are. The use of a flat washer doesn't provide proper torque. Under pressure the gear bends the flat washer and allow the gear to lift or seperate. This will cause loss of pressure or seal failure.

![]()

![]()

Simply by using a grade 8 hardened bolts and lock washer or no washers at all, eliminate this problem. On blocks that have a shallow hole above pressure port , we suggest cutting hardware instead of stacking washer for use a spacer.

There has been so much contraversy over the newest release of the Marzocchi Gear. We have been working hand and hand with the engineers to correct the previous problems that have plagued this to try and help resolve this matter. I've spent hours doing research and testing and have found several problems.

I will finally speak the truth, and reveal what has been done to correct these issues.

1) The relocation and over sized pressure port

2) excess lap tolerence

3) incorrect hardware,mounting of gear

4) Over sized suction port

Here are some Photos of corrections being performed

Insert sleeve 308 stainless, .505 O.D with .050 wall thickness ,is pressed into the .500 pressure port thus making the new port size .400 and keeping port in stock location , making them useable on industry standard block..no new block needed

Adhesive and sleeve being pressed in

Pressed in flush with base. The smaller port makes the gear not flood out as with the bigger port. The larger port definatly has much more flow, but we've achieved a happy medium and get both higher pressures with high flow rates.

with a 20 Ton press the swedge is pushed into the sleeve and flares inside cavity and port

Completed base plate with mating surfaced lapped flat ,where the pretruding flared edge stuck above surface. the top edge of port was machined at a 45 degree counter sink to allow flare to seat and will also not allow it to back out, locking under center section of the gear.

Then the gears center sections are lapped back to Marzocchi specs.

We left the main suction port alone, even know it is over sized by industry standard. Normal port sizing is 40 to 60 % larger for suction port then pressure port. The only down fall I seen from this over sized port is the strength loss taken away of the center section. But ,By using our To-Mar "Gear clamp" this adds the additional strength needed during pressure spikes that would swell or distort this aluminum center section

The last issue I've seen is the incorrect use of pump hardware. The new gears have a cast iron (ductile) top and bottom plate, and are machined flat where mounting hole are. The use of a flat washer doesn't provide proper torque. Under pressure the gear bends the flat washer and allow the gear to lift or seperate. This will cause loss of pressure or seal failure.

Simply by using a grade 8 hardened bolts and lock washer or no washers at all, eliminate this problem. On blocks that have a shallow hole above pressure port , we suggest cutting hardware instead of stacking washer for use a spacer.